Assembly

The assembly area

This is the assembly area of the production facility. This area was redesigned in

2003 in order to ensure an optimized assembly process and even greater

quality assurance.

All stages of the process and their sequence are clearly defined and executed

by trained personnel.

Working process

of installation

In order to achieve

product conformity, the necessary human

and physical factors of the working environment are ascertained and adjusted.

This includes the following aspects:

• location

• equipment

• working conditions

• employee health

• safety

• working methods

• experience

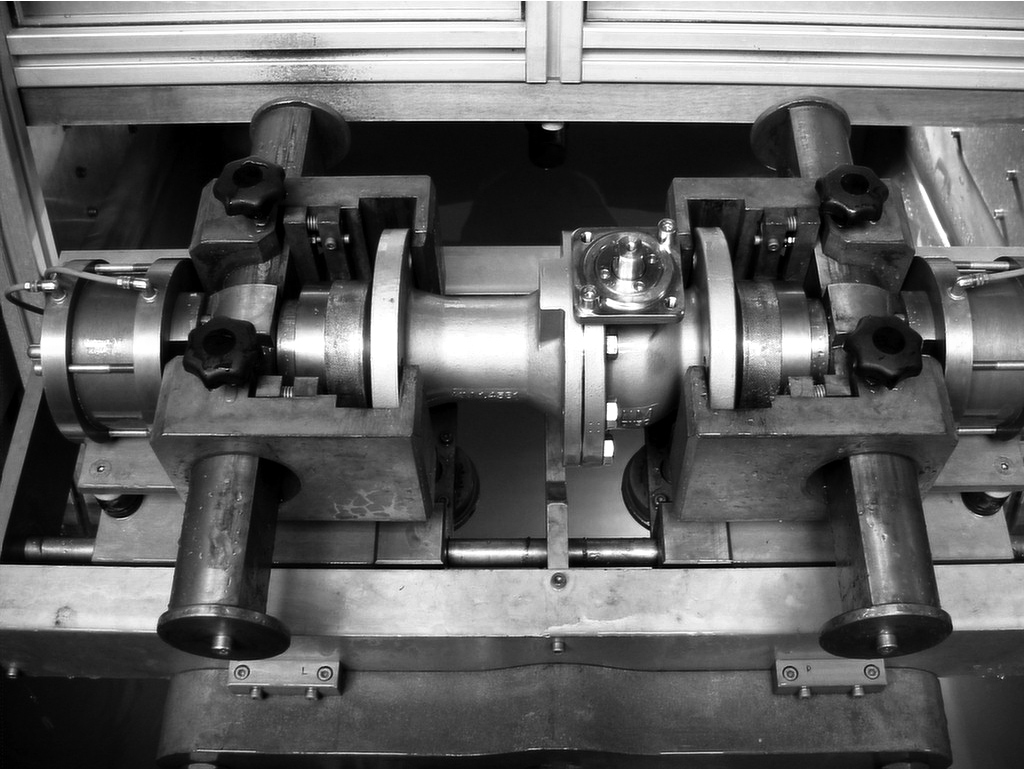

Tightness test

The functioning and tightness of each

valve are tested on one of these test

beds. If they meet the requirements,

they are marked accordingly on the

flange edge.

Due to strict quality assurance during

production, the error rate in these final

tests is almost zero.

Storage

Until delivery, the ball valves are kept in

storage, where they are packed securely

in these pallet cages. The cages are clearly marked and covered with foil to keep

out dirt.

The placement of the pallet cages is

managed by the QM officer so as to

ensure rapid access when the orders

are processed.